- Joined

- May 27, 2012

- Messages

- 759

- Motherboard

- DQ77KB

- CPU

- i7-3770S

- Graphics

- HD4000

- Mac

- Mobile Phone

Yes I could move the PINS around without much issue, but would like to go a little further, to include your fan control architecture, as this really is one of the bigger advances.Hi Kiwi

Maybe you should just order the boards and replace your handmade one. The only thing you could do at this point is to change the pinout in your software to match mine. Then change your board layout to match. This would make the merging process easier later and we would have more available PWM capable pins for future applications.

The problem I discovered is finding a suitable P-Channel MOSTFET, in a suitable small package. TO-92 dont seem to provide high enough current. TO-220 is too large and way over kill. The only package I can find is TO-251 which seem to offer a compromise between the two sizes. Your opinion?

Also P channel requires the additional control transistor. N channels seem to be much more prevelant, and easier to control since a controlling transistor can be removed. But I dont think this is an option, because it controls the GND signal of the LOAD. Am I correct ?

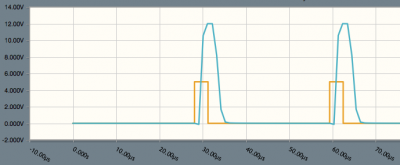

I have simulated this circuit, and I basically works, the only slight issue is the turn off time once the logic level goes to 0, don't know if this is a real issue or could be tweaked with changing component values.

The orange line is the input clock signal, blue is the voltage applied to the Fan.

Can you post some simple code for the fan control logic, and confirm how the hardware for the tachometer works, ie.e what actual signal does this fan pin produce? and how is this converted to RPM.

Thanks as always

Kiwi

Kiwi