- Joined

- Aug 13, 2012

- Messages

- 130

- Motherboard

- GIGABYTE Z97X-UD3H

- CPU

- i5-4690K

- Graphics

- RX 580

- Mac

- Mobile Phone

Build Log 2 - NUC Motherboard Mounting

Deciding where and how to seat the NUC system board took a fair bit of thought processing. I ultimately decided that the most functional and aesthetically pleasing location would be in the space held by the previous DVD drive. There is mixed opinion on scrapping DVD drives, but in this build with it's limited workspace, the DVD had to go. In all honesty, I have a USB DVD writer that I only use maybe a couple of times a year. Its compatible with OSX, so why waste nearly a precious 100 cu in of internal space on a redundant piece of hardware that can easily be managed externally by USB?

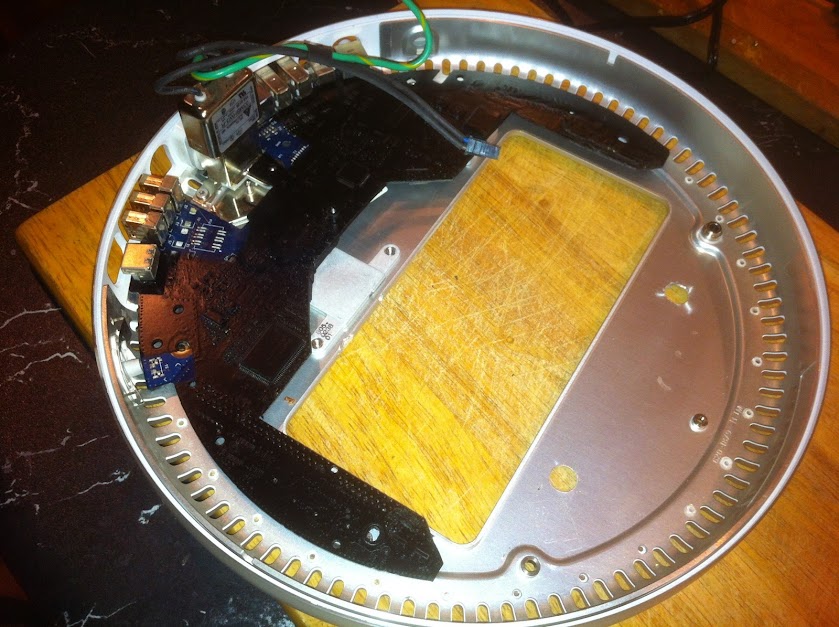

To affix the the rear I/O in position, I decided to cut out a piece of the original G4 motherboard, preserving four of its mounting holes for fastening to the base of the machine. This allowed the rear I/O to remain firmly seated with little re-engineering. Apple had already done the legwork for me, so why re-invent the wheel? I ground off all the capacitors, memory slots etc with my dremel. I gave the original board a real 'clean shave'.

Here's what the original board looks like now, after I painted it black. Several of the rear I/O pieces would later be removed off the board to fit my own. There isn't much left of the original, but what matters is that I preserved four mount holes for a firmly seated fitment.

Here's whats left of the old motherboard. Didn't this used to be round? Rest in Peace.

I then cut a plate of aluminum to fit the base. It is drilled to mate up with three of the four motherboard mounting holes. I used UK Electrical Socket Screws (trimmed to correct length) as the thread pattern matches that of the standoffs in the base. These work great in the Apple mods, and I alway keep a package of long ones on hand for re-purposing. They are readily available on eBay. I chose this shape of mounting plate because it leaves access open to the rear I/O, and doesn't impede the critical airflow that will come in through the base vents all around the bottom of the machine, and doesn't collide with the front DVD door. I used the original NUC base to mount the board. It is mounted firmly to the aluminum plate with 2 bolts as shown. (Note that I hadn't painted the G4 motherboard yet in this photo).

Rearward view of NUC base mounting

To secure the motherboard to the NUC base, access is required from underneath. I drilled four holes in the underside and through the aluminum mounting plate to allow screwdriver access for tightening down the NUC board. It is secured at the top with four original standoffs removed from the NUC case.

The four screwdriver access holes in the bottom (only 2 are really visible)

The NUC firmly secured down using four of its own original standoffs (now on the top) via four screwdriver access holes underneath.

I took this photo through the DVD door. It shows the new interior space for the Intel NUC in the original DVD drive location. The new floor sits within about 2mm of the DVD/HDD rack at the bottom, very close measurement paid off. The aluminum floor still had the protective plastic peeling on it, thats why it appears so white. This looks like a great new home for the NUC to live!

The base installed in the iMac viewed through the DVD door. The NUC fits perfectly in the previous DVD drive location. There is about 1/8" of clearance between the NUC cooling fan and the G4 Hard Drive rack above it. Wow it was tight, but it all fit in there!

Ersterhernd

This may be a silly question, but I'm not very good with electronics yet. If I followed your lead and kept a piece of the motherboard to bolt down the rear IO, how would I ground off everything currently on the board?

Thanks.