OK big guy (minihack

) I have a shiny new G5 just itching to be worked :

"unfortunately" I have H100i cpu cooler. I say that because it's BIG. I wished I had bought the H80i as it's half the size and would have aided easier fit into the new G5 for the sake of few degrees increase in temperature.

I also wished I had bought a microATX motherboard instead of ATX that I have.

I have what I have and love to use them in this case.

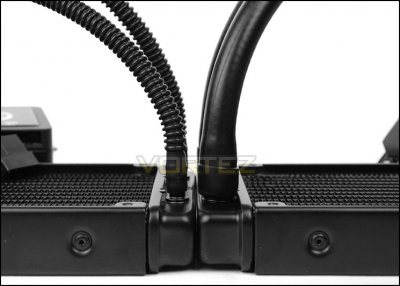

The new H100i is slightly taller than the old H100 (due to the thicker rubber tubes).

The new one is 27.8 cm tall and 12.0 cm wide.

So need advise as to best way to fit it:

1. Vertically : At the front as Intake. PSU at the bottom (where the G5 PSU used to be) ?

2. Horizontally: on the Floor as exhaust where the G5 PSU used to be. New PSU at the top where the HDD bay was.

3. Vertically: At the back as exhaust above the I/O panel - like you have the minihack twin 120 fans.

I am not sure option 3 is possible without squaring curved bottom of the case - even then not sure it's possible.

All suggestions welcomed.