- Joined

- May 27, 2010

- Messages

- 2,364

- Motherboard

- Dell Optiplex 9030 All in One

- CPU

- i5-4690K

- Graphics

- HD 4600

- Mac

- Classic Mac

- Mobile Phone

I have been doing some more re-thinking on the mod and thought it might be nice to make this one more of a specialised water cooling case.

As there is now a huge hole in the roof (!) I started thinking that there is not much reason to have a 120 fan at the back - as it only diverts airflow away from the roof fans.

I also started thinking that if a conventional water cooling system was to be used in a G5 then maybe there is a better - or at least different - way to route pipes and wiring.

So my latest idea is to make a full false back behind the motherboard and route the pipework around there and also give some nice options for a rear mounted watercooling reservoir.

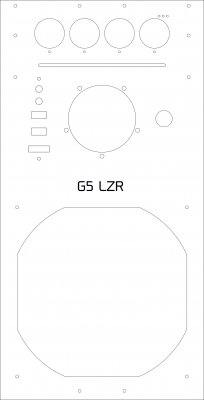

So here are the pic.s of a (another) prototype G5 back which moves everything more towards the door side to leave room underneath the IO area.

Fan replaced by a single 92mm one from the original G5 with original grill.

The large holes under the mobo area are big enough for large water pipes to be routed through or for panel connectors (maybe quick release?) to be attached for that. The small holes in line with them are 4mm holes which allow a variety of choices for mounting brackets for cylindrical reservoirs of any desired height. I've also included mount holes above and below the grill so that a shorter tube reservoir like a 150mm tube could be positioned there if wanted.

Still unsure of the exact panel design for the sides yet.

As there is now a huge hole in the roof (!) I started thinking that there is not much reason to have a 120 fan at the back - as it only diverts airflow away from the roof fans.

I also started thinking that if a conventional water cooling system was to be used in a G5 then maybe there is a better - or at least different - way to route pipes and wiring.

So my latest idea is to make a full false back behind the motherboard and route the pipework around there and also give some nice options for a rear mounted watercooling reservoir.

So here are the pic.s of a (another) prototype G5 back which moves everything more towards the door side to leave room underneath the IO area.

Fan replaced by a single 92mm one from the original G5 with original grill.

The large holes under the mobo area are big enough for large water pipes to be routed through or for panel connectors (maybe quick release?) to be attached for that. The small holes in line with them are 4mm holes which allow a variety of choices for mounting brackets for cylindrical reservoirs of any desired height. I've also included mount holes above and below the grill so that a shorter tube reservoir like a 150mm tube could be positioned there if wanted.

Still unsure of the exact panel design for the sides yet.