- Joined

- Oct 23, 2012

- Messages

- 7

- Motherboard

- X86

- CPU

- C2D E8400

- Graphics

- GTX650TI

- Mac

- Classic Mac

- Mobile Phone

Hello Everybody!

Unfortunatly the building of my Tydirium shuttle is standing in orbit. The vacuum formin machine’s bulding has been stopped for some time, this why I can not proceed with my shuttle. I haven’t been idle for a long time, at the end of July I receeved a chance that I can not refuse.

After long years of waiting I could get my hands on a PowerMacG5 chassis! I planed for a long long time to have one , but because of the price I coluld not get a chance. But in this July at a hungarian IT site’s advertise my friens saw one with a suprising low price, they called me and I negotiated with the owner in the next minute.I one week the chassis has arrived.

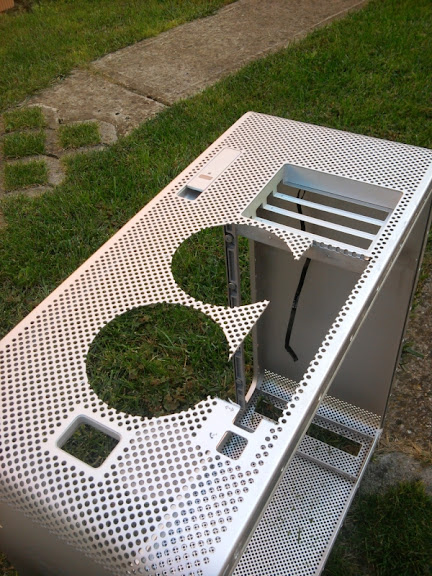

This is the chassis:

In the afternoon I removed all parts from the chassis. It was not an easy task, because I never worked with Powermac machines, I had to stop from time to time and had to think how to remove the next piece from its place..... but finally I has success and that was only important.

Pictures of taking apart the chassis:

I have succesfully removed all the screws, so I can moved out all the parts left in the case. Hurray!!

The case has been naked down totally. I can disable further to an inner core and an outer cover, but without the specific tools this is not gonna happen right now.The case has at least 3 types of screws, which need 3 different type of screwdrivers, so more is needed as a crosshead screwdriver.

My primary goal is to build a PC in this case , without modifying it too much, I am think of the backplate especially. I have to work out the fixing of the mainboard, the PSU and drives.

Thanks for reading!

Unfortunatly the building of my Tydirium shuttle is standing in orbit. The vacuum formin machine’s bulding has been stopped for some time, this why I can not proceed with my shuttle. I haven’t been idle for a long time, at the end of July I receeved a chance that I can not refuse.

After long years of waiting I could get my hands on a PowerMacG5 chassis! I planed for a long long time to have one , but because of the price I coluld not get a chance. But in this July at a hungarian IT site’s advertise my friens saw one with a suprising low price, they called me and I negotiated with the owner in the next minute.I one week the chassis has arrived.

This is the chassis:

In the afternoon I removed all parts from the chassis. It was not an easy task, because I never worked with Powermac machines, I had to stop from time to time and had to think how to remove the next piece from its place..... but finally I has success and that was only important.

Pictures of taking apart the chassis:

The case has been naked down totally. I can disable further to an inner core and an outer cover, but without the specific tools this is not gonna happen right now.The case has at least 3 types of screws, which need 3 different type of screwdrivers, so more is needed as a crosshead screwdriver.

My primary goal is to build a PC in this case , without modifying it too much, I am think of the backplate especially. I have to work out the fixing of the mainboard, the PSU and drives.

Thanks for reading!