- Joined

- May 12, 2012

- Messages

- 107

- Motherboard

- Gigabyte GA-B75M-HD3

- CPU

- i5-2500K

- Graphics

- GT 710

- Mac

- Classic Mac

- Mobile Phone

AppleMacIdiot's First G5 Mod [Updated]

AppleMacIdiot's First G5 Mod

So this is looooong overdue...

I finished a PowerMac G4 mod back in 2012 and threatened to follow it up with a G5 mod. Well, life had other plans. So after almost two years and a life-changing move to the other side of the planet, my new life in the US has finally settled down enough to get back on track with this little project. Yaaaaay!

In a stroke of luck, the G5 case I had gutted back home somehow survived the 3-month trip at sea relatively unscathed and I've also had a lot of time to think about this project. A LOT of time! It also seems that the community has done some pretty amazing work during this time and some great progress has been made, which I have factored into my plans - hence the title of my build.

I purchased my case with some light water damage from what seems to have been a leaky liquid cooling system. I did some basic cleaning out when I originally gutted the system, but it seems the last two years haven't been kind to the damage and I have had some further cleaning, de-rusting and repair up to do.

In this first post I'll take a quick trip through the clean up and repair process, which is almost completed...

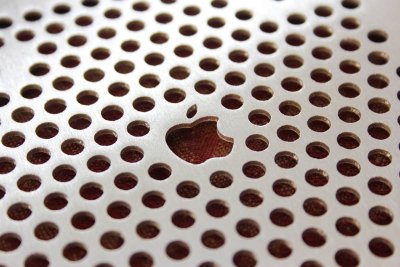

Here's my gutted case. You can see the discoloring near the bottom from my previous cleaning attempt.

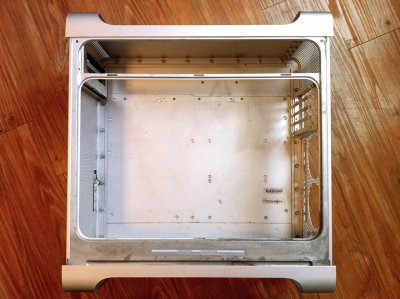

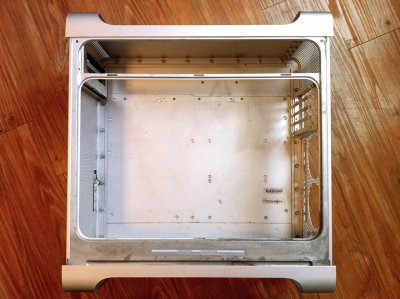

The case stripped down even further to just the cage.

Some slight rust on the main cage section.

After drilling out the rivets and removing the locking / side-panel frame thingy you can see that it took the brunt of the water damage and rusted quite badly.

After some soaking in white vinegar and light scrubbing with a toothbrush things look considerably better. A little light sanding and buffing to smooth out any ridges and it's ready for some paint.

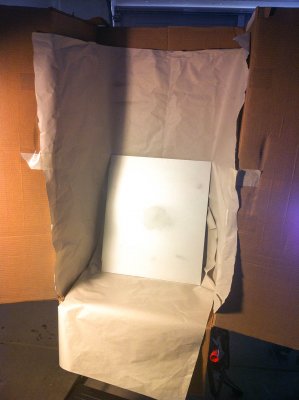

Ready for painting in my quick and dirty paint booth. As you can see, I'm using Rust-oleum Painter's Touch 2x Ultra Cover - Metallic Aluminum (249128). From my test samples the color is an almost exact match with the anodized aluminum of the case with about the same texture. My intention is to spray most of the case to cover up some other blemishes, light scratches and cover-up the body filling that I plan on later

The results. Not 100% perfect, but a million times better than before I reckon!

Here's the part along side the original cage. The colour is a tone darker and a slightly cooler grey than the anodized case, but I'm still very happy with the result. In certain light you can't even tell the difference.

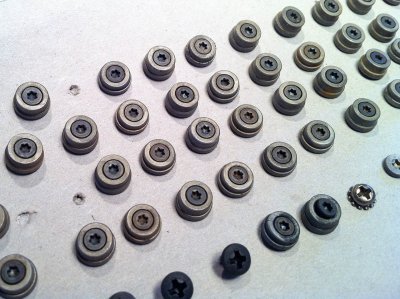

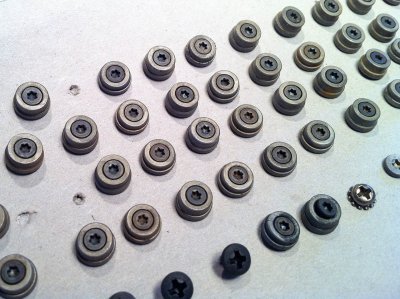

After stripping down the case,you can see that quite a bunch of the case screws were dirty, rusty, grimy, scratched or all of the above. I'm a stickler for even the slightest detail, so these needed attention.

Soaking them in white vinegar for about 10 hours and rinsing them in rubbing alcohol cleaned them up really nicely, but as you can see the stripping process leaves them quite dull and off colour from the original screws.

Pressing them into a sheet of thin card and spraying them with Rust-oleum sorted them out quickly and perfectly...

The result? Almost good as new! Yaaaaay!

That's about it for now. A little more wiping and cleaning the interior and I'll be ready for the next stage.

It has been really slow going thus far, but now that I've FINALLY started the ball rolling again, things should go much quicker in the coming weeks.

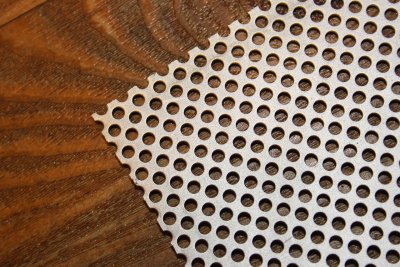

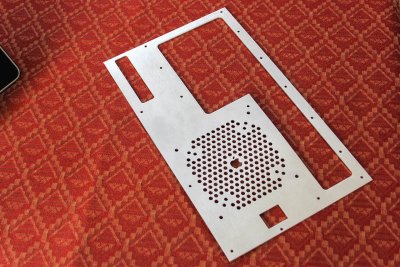

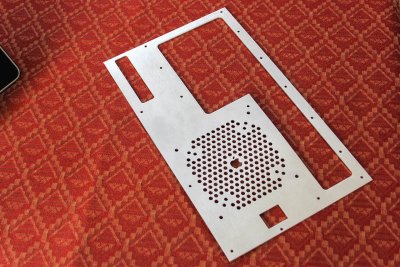

My next update will cover my up-coming attempts at cutting the rear of the case to make way for my custom backplate which I intend mount flush. Check out this sneak peak...

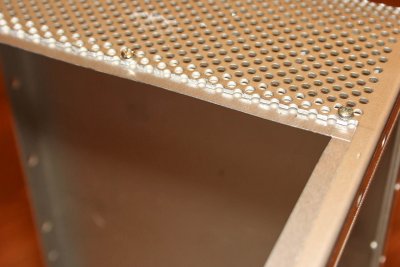

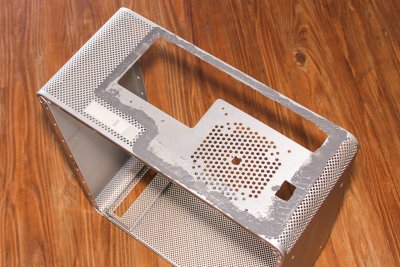

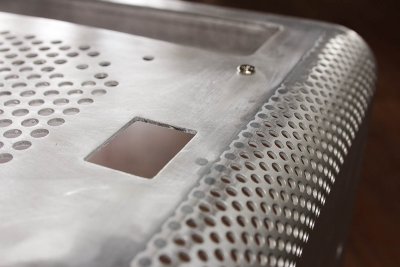

I also have some cool plans for an aluminium motherboard tray, an aluminum airflow / deflector system (similar to the Mac Pro) for improved airflow / fan mounting and a few other little goodies for good measure.

Stay tuned for more...

AppleMacIdiot's First G5 Mod

So this is looooong overdue...

I finished a PowerMac G4 mod back in 2012 and threatened to follow it up with a G5 mod. Well, life had other plans. So after almost two years and a life-changing move to the other side of the planet, my new life in the US has finally settled down enough to get back on track with this little project. Yaaaaay!

In a stroke of luck, the G5 case I had gutted back home somehow survived the 3-month trip at sea relatively unscathed and I've also had a lot of time to think about this project. A LOT of time! It also seems that the community has done some pretty amazing work during this time and some great progress has been made, which I have factored into my plans - hence the title of my build.

I purchased my case with some light water damage from what seems to have been a leaky liquid cooling system. I did some basic cleaning out when I originally gutted the system, but it seems the last two years haven't been kind to the damage and I have had some further cleaning, de-rusting and repair up to do.

In this first post I'll take a quick trip through the clean up and repair process, which is almost completed...

Here's my gutted case. You can see the discoloring near the bottom from my previous cleaning attempt.

The case stripped down even further to just the cage.

Some slight rust on the main cage section.

After drilling out the rivets and removing the locking / side-panel frame thingy you can see that it took the brunt of the water damage and rusted quite badly.

After some soaking in white vinegar and light scrubbing with a toothbrush things look considerably better. A little light sanding and buffing to smooth out any ridges and it's ready for some paint.

Ready for painting in my quick and dirty paint booth. As you can see, I'm using Rust-oleum Painter's Touch 2x Ultra Cover - Metallic Aluminum (249128). From my test samples the color is an almost exact match with the anodized aluminum of the case with about the same texture. My intention is to spray most of the case to cover up some other blemishes, light scratches and cover-up the body filling that I plan on later

The results. Not 100% perfect, but a million times better than before I reckon!

Here's the part along side the original cage. The colour is a tone darker and a slightly cooler grey than the anodized case, but I'm still very happy with the result. In certain light you can't even tell the difference.

After stripping down the case,you can see that quite a bunch of the case screws were dirty, rusty, grimy, scratched or all of the above. I'm a stickler for even the slightest detail, so these needed attention.

Soaking them in white vinegar for about 10 hours and rinsing them in rubbing alcohol cleaned them up really nicely, but as you can see the stripping process leaves them quite dull and off colour from the original screws.

Pressing them into a sheet of thin card and spraying them with Rust-oleum sorted them out quickly and perfectly...

The result? Almost good as new! Yaaaaay!

That's about it for now. A little more wiping and cleaning the interior and I'll be ready for the next stage.

It has been really slow going thus far, but now that I've FINALLY started the ball rolling again, things should go much quicker in the coming weeks.

My next update will cover my up-coming attempts at cutting the rear of the case to make way for my custom backplate which I intend mount flush. Check out this sneak peak...

I also have some cool plans for an aluminium motherboard tray, an aluminum airflow / deflector system (similar to the Mac Pro) for improved airflow / fan mounting and a few other little goodies for good measure.

Stay tuned for more...