- Joined

- Dec 15, 2011

- Messages

- 905

- Mac

- Classic Mac

- Mobile Phone

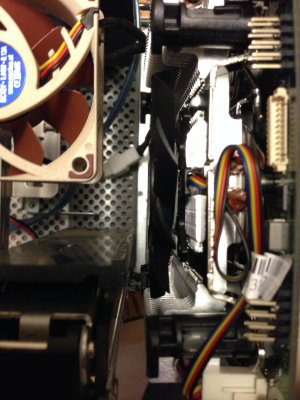

I'm not sure anymore, but I believe, that the springs must be attached to the heatsink.

See here:

MacTester

See here:

MacTester

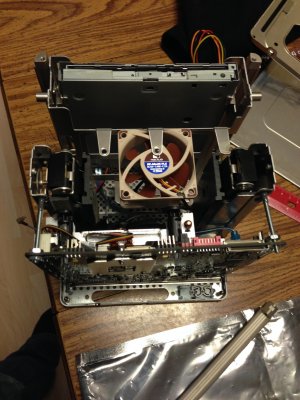

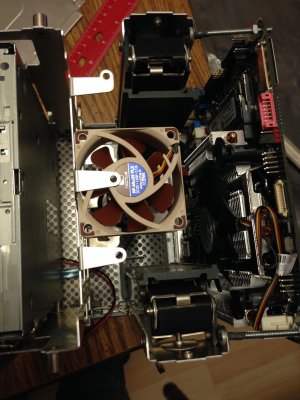

the simple way is to drill holes in the handle assembly, then simply put bolts through the holes and secure with a nut, no glue required, see photos in the following post. I did something similar in my build but used 40mm standoffsAs I'm looking at what others have done, many have had to tap holes for threaded motherboard standoffs either into aluminum blocks or the handle assembly itself. I don't have access to a tap, nor do I really want to purchase one just for this use. Do you guys think putting a nut on the end and j-b welding it to the handle assembly would be enough, or does anyone have another idea that doesn't involve a tap? I'd really want that to be a last resort.

Sadly I have to get somewhere and don't have time to post pics. Will do tomorrow. Thanks for all your help!

Cheers!