- Joined

- Jul 6, 2011

- Messages

- 172

- Motherboard

- Asus Z170i Pro Gaming

- CPU

- i7 6700k @4.6

- Graphics

- 980ti

- Mac

- Classic Mac

- Mobile Phone

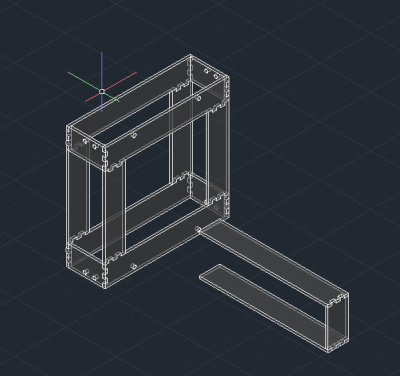

Sorry I haven't updated the project at all, I have been very busy with school and I haven't seen much interest in the project for a while. If people want, I can post pictures of my final build (Don't judge, Its the first time I've ever built a computer).