Hi again, time to show you my progress.

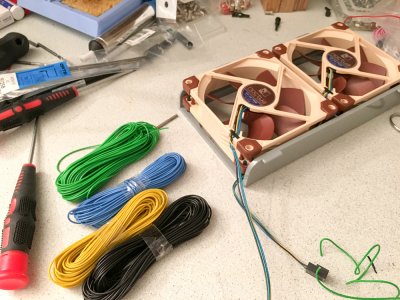

First, my cheap-chinese-paracord finally got delivered and i finished the ATX-power cable. Now all the psu-cables are sleeved. I'm doubting whether i should use cable-combs, but i'll decide when everything is in the case.

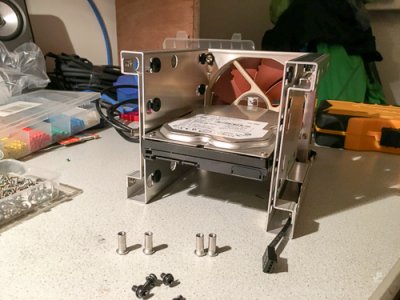

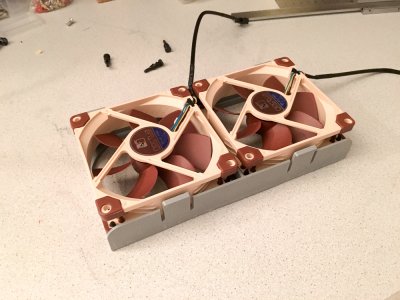

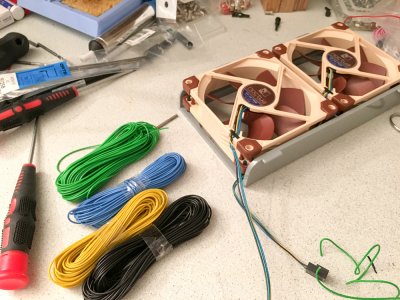

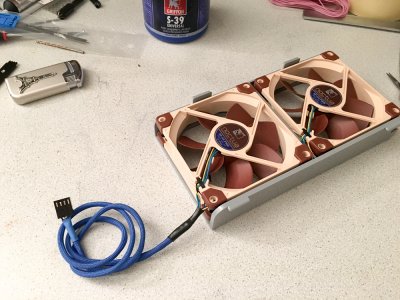

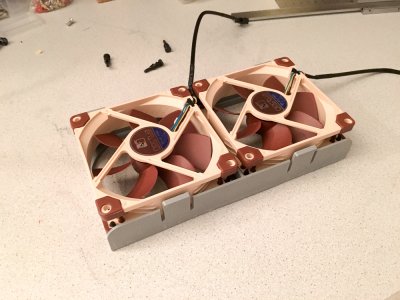

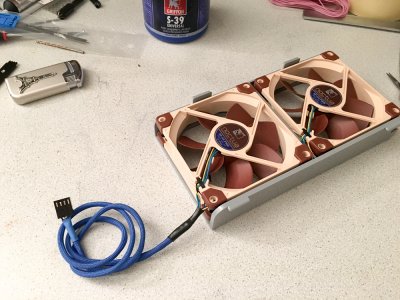

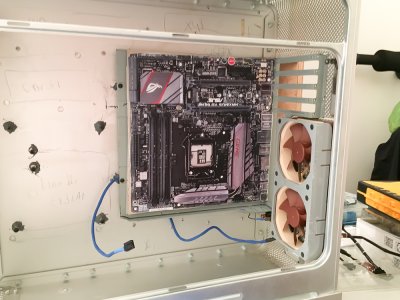

Next, i got the new fans for the rear exhaust. In line with the rest of the case, i'm using 92x25 Noctua PWM fans. They fit nicely in the bracket. I cut the original cables and soldered and sleeved a new cable with a single connector. Since the fans are PWM i won't use the provided LNA, i'll just lower the speed with the motherboard settings if its to loud.

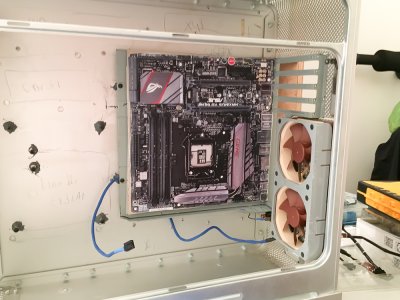

Because i have not chosen a motherboard i made the cable long enough to go to the back and also top of the motherboard, behind the tray.

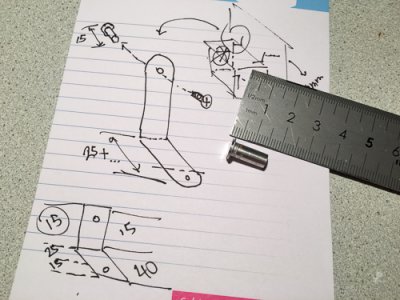

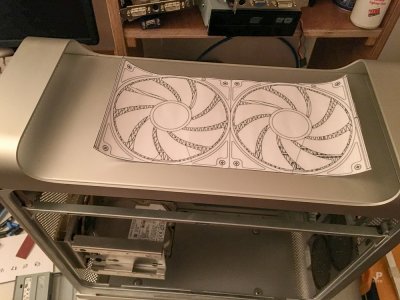

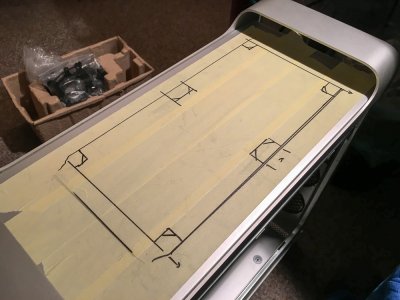

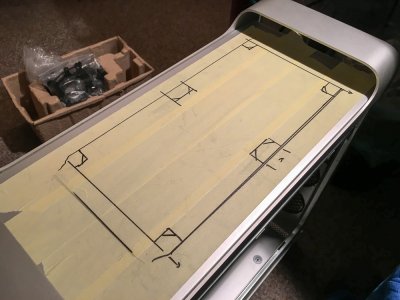

Also, the Kraken X61 is sitting here ready to be built in... I taped of the top of the case and drew the outline of the radiator. Next is creating the 4 corner holes to mount the radiator to the top of the case. I'm not gonna use the provided black screws, because they don't look good on the outside. Also, i want the screws to be countersunk.

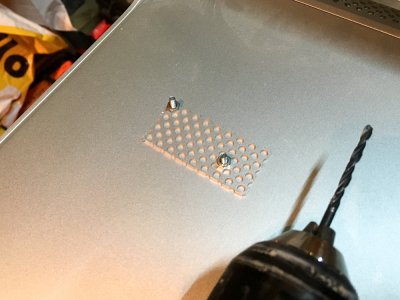

I spent almost a complete evening trying to find out how that crazy UNC system works. Countersunk aluminium colored screws aren't easy to find in Europe. Finally i found a store in Amsterdam where i could order them on-line. They are a bit too long, but then i'll use some washers or cut them.

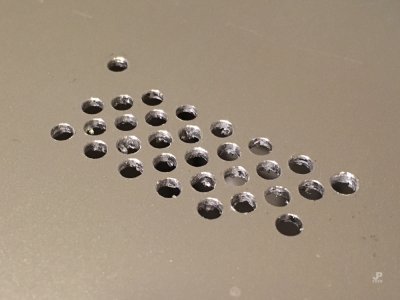

And then begins the task of drilling A LOT of holes. In my last post i said i would drill the 3 mm holes, but i found out that drilling a 2 mm hole first, followed by a 3 mm hole leaves a nicer rim, without a burr.

Luckily, i wont have to draw or measure all the holes, because i can use the front of my second G5 as template. This will speed up the process.

So, quick guesstimate: 280 mm long with a hole every 6 mm is 46 holes, 140 mm wide with a hole every 6 mm is 23 holes. 23 x 46 = 1.058, times 2 for drilling 2 mm first and then 3 mm:

I'm looking at drilling some

2.100 holes... Wish me luck