- Joined

- May 27, 2010

- Messages

- 2,364

- Motherboard

- Dell Optiplex 9030 All in One

- CPU

- i5-4690K

- Graphics

- HD 4600

- Mac

- Classic Mac

- Mobile Phone

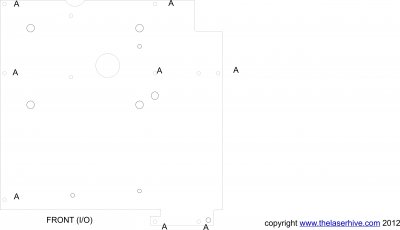

AGPG4Motherboardnew.jpgAttached is a pdf that if printed out full size and the holes cut where marked will lay over the standoffs, holes and posts on an early G4 "door" and show the correct mounting place for ATX type standoffs. This will align your ATX first PCI-e card to go to the first slot on the G4 door.

This is the template that I am using when I make up my perspex motherboard tray for these models but if you just make it from card it will allow you to mark the exact positions for your mATX board without even having to dismantle all the door.

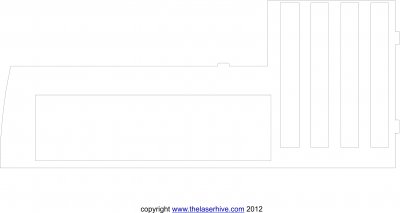

I am fine tuning a blanking plate for the front I/O portion (to make sure the I/O opening is at exactly the right height) that will help also people to make cuts in the right place - or if they use it as a blanking plate can cover up any bad cuts they might make.....

These I hope will help people to make their own G4 conversions - and encourage user jmpa NOT to give up!!!

Important note: I am posting this to help out. I believe it is accurate for the models indicated, but cannot be held liable for it please. If something looks NOT right when you print it out then don't use it. Also note that it assumes you want to use all 4 PCI slots and therefore that unless you choose your mobo carefully or cut the pillar (you will know what I mean...) then audio ports may be obstructed. Any questions on the template you can post on the thread or PM me.

AGPG4Motherboardnew.pdf

This is the template that I am using when I make up my perspex motherboard tray for these models but if you just make it from card it will allow you to mark the exact positions for your mATX board without even having to dismantle all the door.

I am fine tuning a blanking plate for the front I/O portion (to make sure the I/O opening is at exactly the right height) that will help also people to make cuts in the right place - or if they use it as a blanking plate can cover up any bad cuts they might make.....

These I hope will help people to make their own G4 conversions - and encourage user jmpa NOT to give up!!!

Important note: I am posting this to help out. I believe it is accurate for the models indicated, but cannot be held liable for it please. If something looks NOT right when you print it out then don't use it. Also note that it assumes you want to use all 4 PCI slots and therefore that unless you choose your mobo carefully or cut the pillar (you will know what I mean...) then audio ports may be obstructed. Any questions on the template you can post on the thread or PM me.

AGPG4Motherboardnew.pdf