- Joined

- Apr 26, 2012

- Messages

- 74

- Motherboard

- Z68ma-D2H-B3 UEFI U1C Bios

- CPU

- i5 2500k

- Graphics

- Gigabyte GTX 970 Mini

- Mac

- Classic Mac

- Mobile Phone

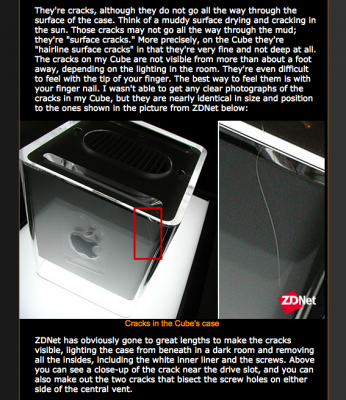

Hello! Long time lurker here on cube mods. I finally went ahead and purchased a cube after weeks of watching eBay listings.The cube finally came and it was damaged in shipping. Very minor I would say but it's still a crack and I am seeking advice on how to prevent it from spreading and getting worse. After looking at all of these case mods I'll be pulling inspiration from multiple but I will be following more closely the French G4 cube mod featured here: http://forums.bit-tech.net/showthread.php?t=227181

and the top will ressemble this:

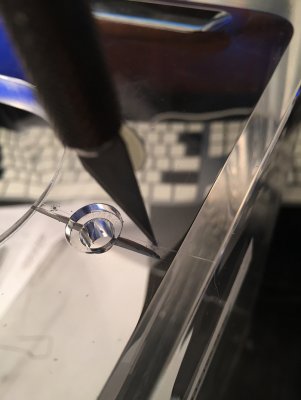

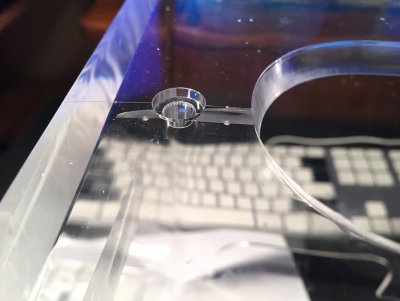

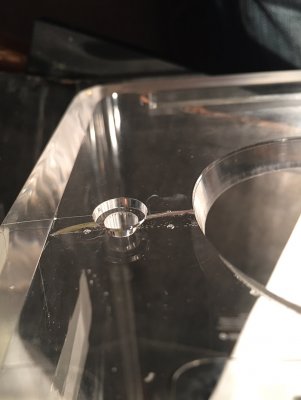

Though here's mine:

So, I will be painting and cutting the outer case so aesthetics on crack repair aren't a priority. Though, my concern is that if I take to cutting the thick plastic (polycarbonate? Acrylic? What is the cube made of?) that the crack will spread or it will break or shatter beyond repair. It's over one of the bolts that secures the inner casing to the outer so it's important that it stay intact.

Reading a bit online about crack repair I've read that I should do a 'stop drill' on the crack to stop it from spreading. Then I'll have a hole there... So, I was thinking about filling it with an epoxy and sanding it down. Would that hold up and not be brittle? Or would I need to reinforce the back with fiberglass? Another idea was to use a body filler, Bondo glass has fiberglass in it already or use another body filler and sanding that down. I read about taking a dremel over the crack and then filling that in essentially replacing the stress crack with a cut which relieves the pressure. There are many tutorials on repairing car bumpers, boats, and motorcycle plastic cracks. There seems to be a wealth of information and many options so I'm a bit lost.

Really, I'm looking for a good solution that will fill the crack and make it stronger so that it won't get worse. It needs to accept paint once it has been prepped and sanded down. Also be able to withstand brief vibration when the top is being cut. I haven't had any experience repairing cracks and it seems that I have a few options but before I commit to drilling/sanding/repairing I was looking for some feedback! Or.... should I not even bother and hope it'll be okay? it's running close to the thick walls but I don't want to fear for its longevity. I think I'll need to open the crack up either way to fill it, so here are my options:

Thanks!!

and the top will ressemble this:

Though here's mine:

So, I will be painting and cutting the outer case so aesthetics on crack repair aren't a priority. Though, my concern is that if I take to cutting the thick plastic (polycarbonate? Acrylic? What is the cube made of?) that the crack will spread or it will break or shatter beyond repair. It's over one of the bolts that secures the inner casing to the outer so it's important that it stay intact.

Reading a bit online about crack repair I've read that I should do a 'stop drill' on the crack to stop it from spreading. Then I'll have a hole there... So, I was thinking about filling it with an epoxy and sanding it down. Would that hold up and not be brittle? Or would I need to reinforce the back with fiberglass? Another idea was to use a body filler, Bondo glass has fiberglass in it already or use another body filler and sanding that down. I read about taking a dremel over the crack and then filling that in essentially replacing the stress crack with a cut which relieves the pressure. There are many tutorials on repairing car bumpers, boats, and motorcycle plastic cracks. There seems to be a wealth of information and many options so I'm a bit lost.

Really, I'm looking for a good solution that will fill the crack and make it stronger so that it won't get worse. It needs to accept paint once it has been prepped and sanded down. Also be able to withstand brief vibration when the top is being cut. I haven't had any experience repairing cracks and it seems that I have a few options but before I commit to drilling/sanding/repairing I was looking for some feedback! Or.... should I not even bother and hope it'll be okay? it's running close to the thick walls but I don't want to fear for its longevity. I think I'll need to open the crack up either way to fill it, so here are my options:

- Drill/epoxy

- Epoxy putty stick for plastic

- Drill/body filler/fiberglass on inside

- Drill/fiberglass bondo

- Super glue

- Ignore it and hope it won't get worse

- Other plastic-specific products I'm not aware of

Thanks!!